-

HOME

-

Products

Products

-

About Us

-

quality & services

-

News

-

CONTACT US

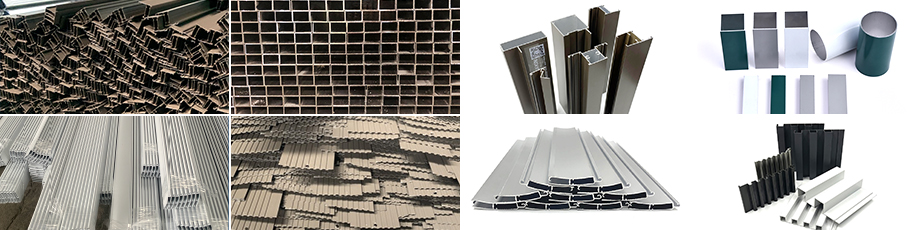

The integrity of your rolling shutters hinges on one foundational component: the aluminum profile. Selecting the wrong supplier for these powder-coated extrusions can lead to a cascade of failures—cosmetic, functional, and financial. While price is a factor, an overemphasis on cost often masks risks that compromise product longevity and brand reputation.

This guide exposes the 7 most critical pitfalls in the supplier selection process and provides a proven framework for evaluation, empowering you to secure profiles that are built to last.

The Trap: To cut costs, suppliers may use non-standard alloys or inferior aluminum. This results in profiles lacking the necessary tensile strength and stiffness, directly jeopardizing the structural integrity and long-term durability of the shutters. A weak base profile can lead to warping under load or even failure in extreme conditions.

The Guide: Always demand a certified Material Test Report (MTR) that specifies the alloy (e.g., 6063-T5) and its mechanical properties. High-quality, standardized alloy is non-negotiable—it's the foundation upon which a perfect, durable coating is built.

The Trap: Inadequate cleaning, degreasing, and chemical conversion coating (chromating or zirconium-based) before powder application. This critical step failure leads to poor coating adhesion, resulting in eventual blistering, peeling, and corrosion that starts at the edges of your shutter slats.

The Guide: Inquire specifically about the supplier’s pre-treatment line technology and quality control checks. A professional supplier will document their process parameters and can provide coating adhesion test results (e.g., cross-cut test per ISO 2409) as standard evidence of quality.

The Trap: The use of low-quality or recycled powder results in coatings with poor UV resistance, color consistency, and mechanical toughness. Your shutters may fade prematurely, develop a chalky surface, or chip easily during handling and installation, leading to customer complaints.

The Guide: Specify requirements for premium, weather-resistant powder brands and define clear standards. Crucially, stipulate a minimum coating thickness (we recommend 60-80 microns for shutter applications) and require certified salt spray resistance data (qualified coatings for coastal or harsh environments should withstand 1,000+ hours).

The Trap: Profiles with excessive twist, bow, or inconsistent cross-sectional dimensions cause misalignment during high-speed frame assembly. This results in shutters that jam, operate noisily, or fail to provide a smooth, complete seal, impacting performance and brand perception.

The Guide: Require detailed profile drawings with explicit geometric tolerance callouts. A capable supplier employs strict Statistical Process Control (SPC) to ensure consistency from extrusion through cutting. Ask for their capability data (Cp/Cpk) for critical dimensions.

The Trap: Flimsy, cost-saving packaging leads to scratches, dents, and coating damage during transit. You receive defective goods before installation even begins, causing project delays, wasteful returns, and unexpected costs.

The Guide: Evaluate the supplier's standard and export packaging protocols. Insist on protective measures like individual foam or paper sleeving for each profile, reinforced corners, and sturdy, weather-proof wooden crates for sea freight. This is a direct reflection of their attention to detail.

The Trap: A supplier offering only catalog items cannot support innovative designs. When your shutter requires a modified groove, a specific drainage channel, or a proprietary connection detail, you're forced into expensive and time-consuming secondary machining.

The Guide: Probe their in-house tooling (die) design and modification capabilities. Present a conceptual drawing and assess their engineering team's ability to provide constructive Design for Manufacturability (DFM) feedback. A true partner helps optimize your design for both performance and cost-effective production.

The Trap: Lax final inspection allows defective products—with color mismatches, thin coatings, or dimensional flaws—to be shipped. When issues arise, vague contracts lead to protracted disputes over liability, replacement costs, and project delays.

The Guide: Audit their Quality Control流程. Do they perform 100% visual inspection and batch-wise tests for coating thickness, color (using spectrophotometers), and adhesion? Most importantly, secure clear, written terms for quality issue resolution, including replacement logistics, deadlines, and cost responsibilities.

Sourcing coated aluminum profiles is a technical investment. The lowest bid often carries hidden expenses in rework, returns, and reputational damage. A true partner operates with transparency in materials science, process control, and quality assurance, offering collaborative support from design to delivery.

At HXALU, we specialize in precision-engineered extrusion solutions for demanding rolling shutter applications. Our profiles are designed for optimal strength-to-weight ratio and assembly efficiency. Our dedicated, automated powder coating line ensures superior finish durability, backed by full material traceability, batch-specific test reports, and a commitment to zero-defect logistics.

Ready to Build with Unshakable Confidence?

Contact HXALU today for a no-obligation technical consultation. Let us provide you with a free, comprehensive project evaluation and a tailored sample kit to test against your toughest standards. Discover how our commitment to precision and partnership can become the foundation of your most successful rolling shutter products.