QUALITY SERVICE GUARANTEE

In 2014, Huixin has got the ISO 9001 certification. We have been following this quality control system strictly to ensure stable quality. From raw material to on-line production and final products, we carry out inspection carefully.

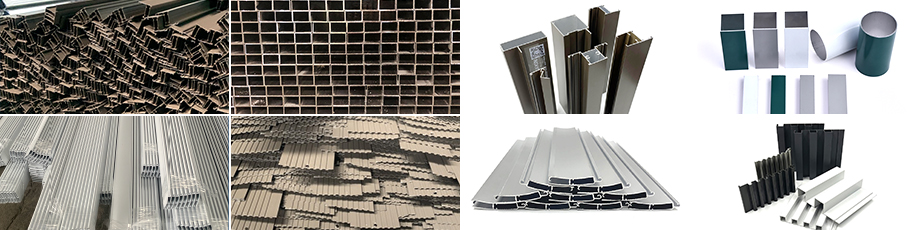

Huixin provides ODM, OEM services to clients. We offer design review, mold development, aluminum extrusion, finishing, packaging, and delivery.

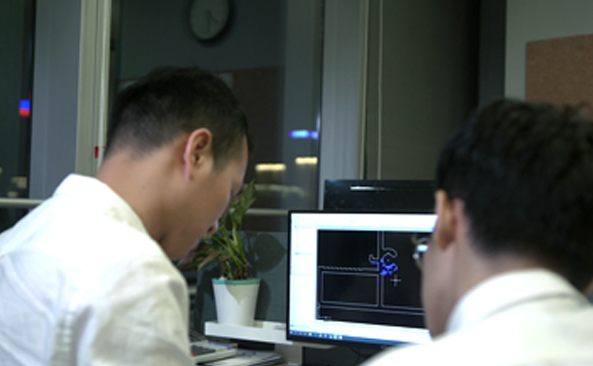

R&D ABILITY AND SERVICE

With a professional engineering team, strong R&D ability is guaranteed. Based on clients' requirements or samples provided, design solution could be provided within 2 days. With more than 12 years experience, cost-saving and qualified product design based on local market's using habit are guaranteed to our clients.

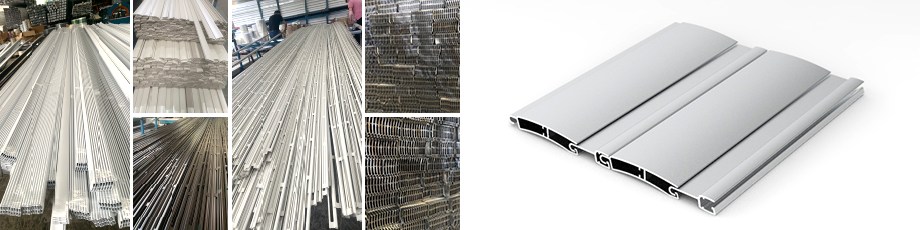

PRODUCTION PROCESS BASED ON NATIONAL STANDARD

01 Prepare Extrusion Die

Before extrusion, the die must be preheated to between 450-500 degrees celsius to help maximize its life and ensure even metal flow.

02 Preheat Aluminum Billet

Then preheat it in an oven to about 400-500 ℃. This process makes the billet malleable enough to carry out the operation. It also ensures that it is not molten.

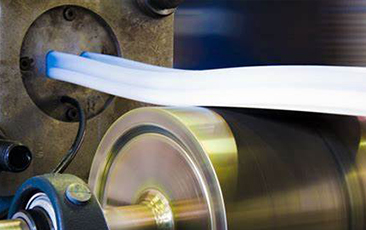

03 Extruding

The heated aluminum billet is pushed through the openings in the tool. Those openings can be modified to create different shapes and sizes.

06 Aging

Qualified extrusions are put into the aging oven to bring the material back to its original hardness.

05 Stretching

The extruded bars are run through a strengthening process, which stretches the bars and ensures their mechanical properties by removing the internal tension within the bars.

04 Controlled cooling

The quenching process is necessary to ensure the required mechanical properties and adequate material microstructure.

07 Finishing

After aging, profiles are transported to the specialized workshop to add finishes like anodized finishes.

STRICT QUALITY CONTROL

Critical specification test

Color difference inspection

Treatment quality inspection

Surface inspection